|

|

||

| Kellscraft

Studio Home Page |

Wallpaper

Images for your Computer |

Nekrassoff Informational Pages |

Web

Text-ures© Free Books on-line |

|

We Meet the Makers of the House (and It's Not Who You Might Think!) With all the information gathered so far, we surely had

everything we needed to know about the house. We knew the architect,

the general contractor, the plumbers and painters. What else could

there be? Actually, quite a bit. It

was an off-hand conversation with a person who was married

to a member of the last family to live in the house. Over coffee on the

porch one summer's day, she mentioned that there were beams in the

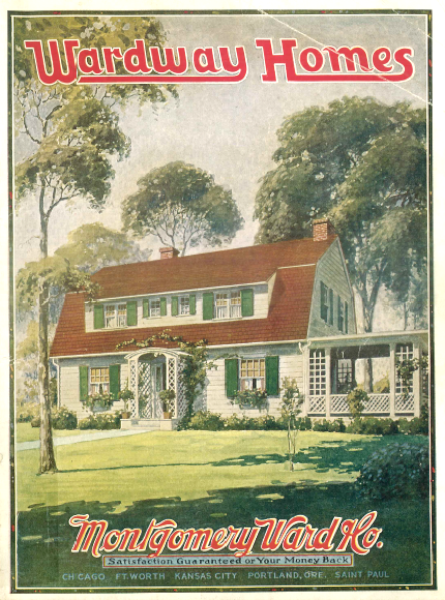

house that were numbered and that this was actually a 'Montgomery Ward'

house. Not something we were familiar with at the time. Of course we

had

heard of the Sears kit houses from the turn of the last century that

you could buy pre-built, which would be milled and then shipped to your

building site, ready to be assembled. The best known of this type would

be the Sears-Robuck kit houses, listed and sold through special

catalogs. Of course, they weren't the only game in town. I found the

following list at just one website online:

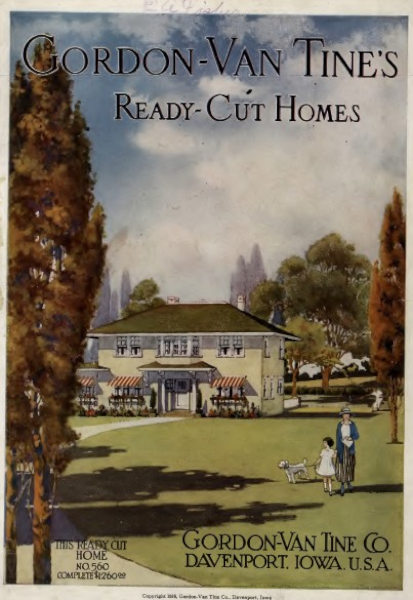

This was a huge market that opened up in the early 1900's,

taking advantage of the post-WWI economy, the railroad infrastructure

that existed at the time and the wish for people to own their own

affordable homes. At first, most of these companies offered ready-made

plans that could be purchased and used to build a house through a local

contractor with local supplies. Some of the larger companies

quickly saw the opportunity to mass-produce kit houses in massive

factories in the Mid-West and ship the house components to nearly

anywhere in the U.S. and Canada. So long as there was a rail depot in

the town, this would be a cost-effective way for a family to own their

own home. Kit houses originally would be sold for the full purchase

price, but the manufacturers saw the potential to hold a mortgage on

these homes and let the home owners pay over time. All of this worked

well in the heyday of the Roaring Twenties, until it all came tumbling

down after the 1929 Stock Market crash and the following Great

Depression. Montgomery

Ward (Gordon-Van Tine) kit house sales is a case in point. Montgomery

Ward began offering mortgages for their house kits, but by the

Depression, people were unable to pay and the kit house sales division was closed down in the 1931. At that same time Gordon-Van Tine stopped making Wardway kit houses. Gordon-Van Tine made an estimated 54,000 kit houses under their name and another 20,000 homes for Wardway (Montgomery Ward) from 1917 to 1930. Gordon-Van Tine remained in business until 1946, when it was sold to a salvage firm.

So where does this leave our research? Well, we have a number

of hints and a few actual examples that this was a special order

Gordon-Van Tine house, modified (let's say up-scaled) by the architect,

Horace T. Muzzy. And Muzzy? We've gained a bit of knowledge about him,

pieced together from the internet.

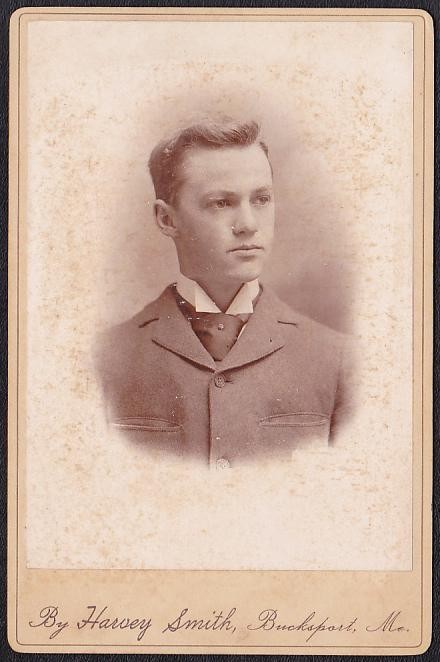

Born in Searsmont, Maine in 1874, Muzzy attended Boston University for two years before transferring to Massachusetts Institute of Technology (MIT), earning a degree related to Architecture. Working at first as an architect for firms in Boston, he had established his own architectural design firm in Waterville, Maine by 1915. From one of his obituaries:

Clearly, soon after opening his own architectural firm in

Waterville, he was making a reputation for himself. Within four years

of returning to Maine, he was hired to draft plans for the Maine

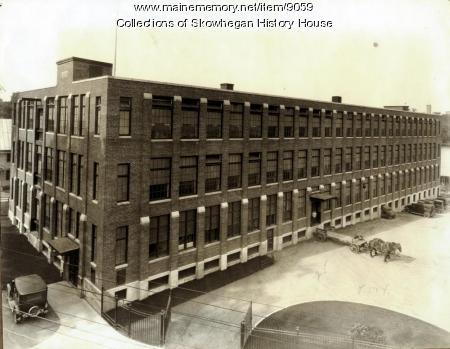

Spinning Mill house for the board of trustees to use. This while the

Maine Spinning Mill was rennovated and expanded in 1923 by a

sought-after architectural firm known for their work on mills -- Lockwood, Greene and Co. More on the Maine Spinning Mill in a later section...  Maine Spinning Mill, Skowhegan, ME. ca. 1925 From the Skowhegan History House Collection So how did Muzzy link up with the Gordon-Van Tine

Company? We don't know the answer to that. Gordon-Van Tine offered upgrades

and design changes as part of their service and it is likely the Maine

Spinning Mill and Muzzy saw an opportunity to have the house built

quickly and with little fuss. By having the house completed before the

Maine Spinning Mill major rennovations were begun in 1923, the Board

had a place to stay in Skowhegan as the Mill upgrades took place.

Possibly... And what about the information from The American Contractor

magazine? Well, someone had to put it all together at the site. That is

where the general contractor, Otto T. Nelson Company, got involved.

Massive bundles of separate rafters, beams, window and door frames,

stair components, floor boards and wall studs, all made to

specification, were shipped by rail car from Davenport, Iowa. Here at

the Skowhegan, Maine depot, Nelson's workers carted the neat bundles

to the worksite on West Front Street, just a few hundred yards

from the Mill factory and started the assembly. Foundation in the

ground in September, 1920, it makes one wonder if they worked on

raising the house that fall, and was it complete by the Spring of 1921?

We'll likely never know, but the speed with which these kit houses

could be completed was well-known.

Kit house at the Davenport, Iowa factory, waiting to be loaded on box cars and shipped to the new owner. Gordon-Van Tine catalog, 1916, pg 6. Next time: We Find Evidence for a Gordon-Van Tine Modified Kit House |